Starting at the wrong end

"The asphalt contractors, customers and authorities in Norway have all set tough climate targets. But it is impossible to achieve the necessary reductions with the current focus primarily on electric vehicles and machinery. These account for less than 20% of the total emissions from raw materials, production and laying of asphalt in Norway. The use of hydrogen in the plants alone can reduce overall emissions by 40%, and the environment doesn’t distinguish between direct and indirect emissions," says Martin Holmqvist, director of Veidekke Asphalt.

Hydrogen is the future in Europe

"Germany and large EU countries recognise that hydrogen is the most realistic emission-free energy option for, among other things, asphalt production. And hydrogen can be produced by wind turbines even when it is windy, from solar parks in summer and hydropower during precipitation peaks. That is why there is so much interest from other countries in our production of asphalt with hydrogen in Kristiansund this autumn," says Øivind Larsen, EVP of Veidekke Infrastructure.

Wise and courageous politicians required

"We are rapidly approaching 2030, and it will take great courage and innovative thinking to reduce greenhouse gas emissions enough to make a properly difference. We are completely dependent on clear guidelines and priorities, both politically and from our customers, in order to meet our shared climate commitments. We have now proven that it is possible to produce with hydrogen alone, and can use large volumes at our 25 asphalt plants if there is full-scale industrial production and distribution of hydrogen in Norway," Larsen concludes.

The production of asphalt is a significant source of emissions with approx. 400,000 tonnes of CO2 in Norway each year. An asphalt plant requires so much energy that electricity cannot be used in production, and the alternatives so far have been gas, propane, diesel, biodiesel and wood pellets, all of which have their own greenhouse gas emissions. In addition, the EU has adopted stricter requirements for the use of forests and has made clear that the use of wood and pellets for energy purposes will be limited (the Renewables Directive) from 2027.

For further information, please contact:

Executive Vice President Øivind Larsen of Veidekke Infrastructure, tel. +47 90 58 23 51, oivind.larsen@veidekke.no

Martin T. Holmqvist, director of Veidekke Asfalt, tel. +47 92 67 12 63, martin.holmqvist@veidekke.no

Communications Manager Helge Dieset, Veidekke, tel. +47 90 55 33 22, helge.dieset@veidekke.no

Veidekke’s press photos

Subscribe to releases from Veidekke

Veidekke is one of Scandinavia’s biggest contractors In addition to undertaking all types of building and civil engineering assignments, the group also maintains roads and produces asphalt and aggregates. Veidekke emphasises stakeholder involvement and local experience. Annual turnover is approx. NOK 39 billion, and almost half of its 8,000 employees own shares in the company. Veidekke is listed on the Oslo Stock Exchange and has posted a profit every year since its inception in 1936.

| Title | File type |

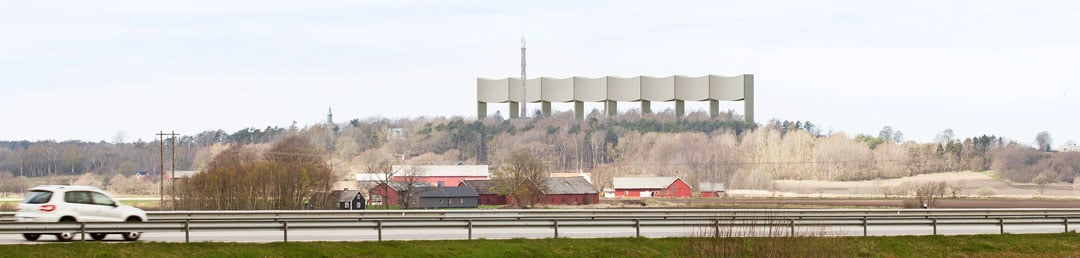

| Kr sund hydrog | JPG |